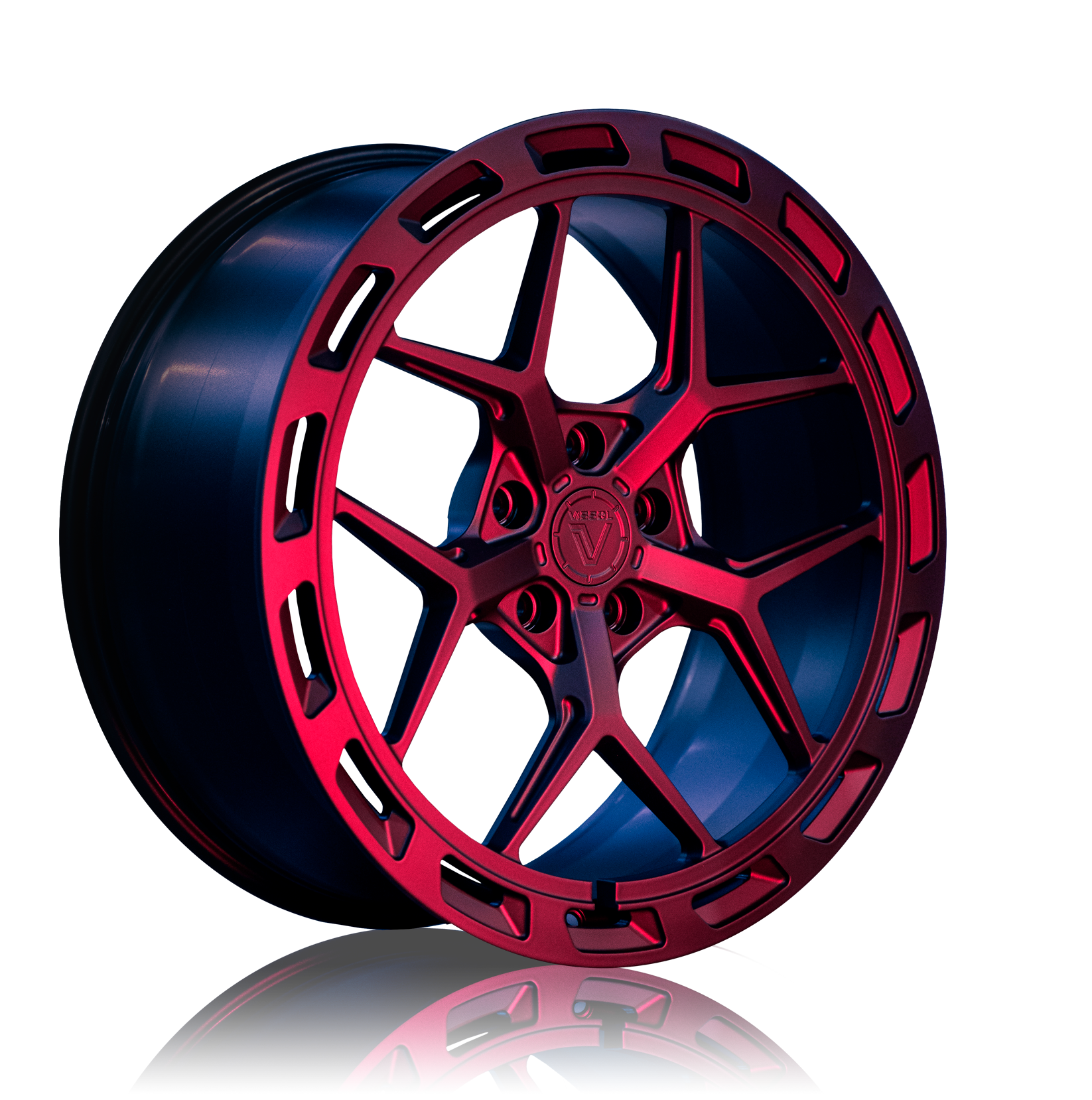

Vissol — FORGED WHEELS PRODUCTION IN RUSSIA

VISSOL — FORGED WHEELS PRODUCTION IN RUSSIA

PLEASE FILL IN THE FORM

By clicking the button, you consent to the processing of personal data in accordance with the privacy policy and accept the terms of the user agreement.

BIGGEST PRODUCTION IN RUSSIA

We control all the production processes by ourselves. The one and only production facility is based in Russia. We don't rely on other factories making products under our brand and hence can guarantee the quality of our products.

LIFE-TIME WARRANTY

Quality is of utmost importance to us and we take it very seriously, that is why all Vissol wheels have life-time warranty.

PRODUCTION TIME

We value your time and hence our production time beats all records. Wheels can be produced in less than a week time since the 3D model confirmation.

CERTIFIED PRODUCTION

Our production facility ensures the best quality control management and has undergone ISO certification.

ANY CUSTOM DESIGN

We produce unique wheels for sport and premium class cars. No one will have anything similar.

WHY Choose VISSOL ?

05/Black

Black

colour solutions

We have a variety of colours availiable or we can make the wheels any other colour according to your request.

01/Titan

Gloss, matt, satin

Gloss, matt, satin

10/Bronze dark

Gloss, matt, satin

12/Bronze cognac

Gloss, matt, satin

07/Bronze gold

Gloss, matt, satin

09/Bronze light

Gloss, matt, satin

08/Bronze standart

Gloss, matt, satin

11/Brown

13/Black

Gloss, matt, satin

23/Gray

Gloss, matt, satin

18/Graphite very dark

Gloss, matt, satin

21/Gold red

Gloss, matt, satin

22/Gold

Gloss, matt, satin

06/Silver

Gloss, matt, satin

05/Silver hyper

Gloss, matt, satin

03/White

Gloss, matt, satin

19/Graphite sparkle

Gloss, matt, satin

14/Graphite standart

Gloss, matt, satin

16/Graphite light

Gloss, matt, satin

15/Graphite very light

Gloss, matt, satin

02/Gun metal dark

Gloss, matt, satin

04/Gun metal standart

Gloss, matt, satin

Gloss, matt, satin

20/Sandy

17/Graphite dark

Gloss, matt, satin

Transparent: Gloss, matt, satin

38/Titan

Transparent: Gloss, matt, satin

39/Candy gold

Transparent: Gloss, matt, satin

37/Platinum

Transparent: Gloss, matt, satin

36/Beege

25/Dark smoke

Transparent: Gloss, matt, satin

26/Gold

Transparent: Gloss, matt, satin

27/Black smoke

Transparent: Gloss, matt, satin

29/Cocgnac bronze

Transparent: Gloss, matt, satin

30/Bronze

Transparent: Gloss, matt, satin

31/Cooper

Transparent: Gloss, matt, satin

32/Graphite very light

Transparent: Gloss, matt, satin

33/Gun metal

Transparent: Gloss, matt, satin

34/Light smoke

Transparent: Gloss, matt, satin

Transparent: Gloss, matt, satin

35/Blue

28/Dark brown

Transparent: Gloss, matt, satin

01/Titan

Gloss, matt, satin

Gloss, matt, satin

10/Bronze dark

Gloss, matt, satin

12/Bronze cognac

Gloss, matt, satin

07/Bronze gold

Gloss, matt, satin

09/Bronze light

Gloss, matt, satin

08/Bronze standart

Gloss, matt, satin

11/Brown

13/Black

Gloss, matt, satin

23/Gray

Gloss, matt, satin

18/Graphite very dark

Gloss, matt, satin

21/Gold red

Gloss, matt, satin

22/Gold

Gloss, matt, satin

06/Silver

Gloss, matt, satin

05/Silver hyper

Gloss, matt, satin

03/White

Gloss, matt, satin

19/Graphite sparkle

Gloss, matt, satin

14/Graphite standart

Gloss, matt, satin

16/Graphite light

Gloss, matt, satin

15/Graphite very light

Gloss, matt, satin

02/Gun metal dark

Gloss, matt, satin

04/Gun metal standart

Gloss, matt, satin

Gloss, matt, satin

20/Sandy

17/Graphite dark

Gloss, matt, satin

Transparent: Gloss, matt, satin

38/Titan

Transparent: Gloss, matt, satin

40/Red candy

Transparent: Gloss, matt, satin

39/Candy gold

Transparent: Gloss, matt, satin

37/Platinum

Transparent: Gloss, matt, satin

36/Beege

25/Dark Smoke

Transparent: Gloss, matt, satin

26/Gold

Transparent: Gloss, matt, satin

27/Black smoke

Transparent: Gloss, matt, satin

29/Cocgnac bronze

Transparent: Gloss, matt, satin

30/Bronze

Transparent: Gloss, matt, satin

31/Cooper

Transparent: Gloss, matt, satin

32/Brown

Transparent: Gloss, matt, satin

33/Gun metal

Transparent: Gloss, matt, satin

34/Light smoke

Transparent: Gloss, matt, satin

Transparent: Gloss, matt, satin

35/Blue

28/Dark brown

Transparent: Gloss, matt, satin

The textured surface of the metal is obtained by scratching the wheel in a set direction.

BRUSHED

The technology of processing the facial part of the wheel to highlight individual design elements.

DIAMOND CUT

PRODUCTION STAGES

Our factory has implemented ISO 9001 international quality system standards. The design development and production of Vissol wheels is carried out in strict accordance with the TSE, VIA and JWL international industry standard.

WHEEL BLANK, THERMAL TREATMENT, PRESSING

For Vissol wheels production we use 6061T alloy. It is based on aluminum with alloying additives of magnesium, copper, silicon, zinc and other metals, and is mainly used in aircraft industry.

The blank undergoes 2 thermal treatment operations — quenching and tempering to relieve internal stresses in the metal.

Each blank undergoes several pressing operations, after which a solid wheel is formed without any spokes and holes on the facial side.

WHEEL BLANK

THERMAL TREATMENT

PRESSING

3D MODEL DEVELOPMENT

A design engineer makes a 3D model in a special program, taking into account all your desires of design, concavity and weight. In order to improve the strength characteristics of the wheel and to make a safe-to-use product, our specialists calculate the maximum load of the wheel and apply a safety margin based on the weight of the car and design features.

Any kind of customisation is possible.

In case your car was tuned or has uknown specifications due to its rarity, you don't need to worry if our wheels will fit your car or not. With a 3D scanner we will get all the dimensions from your car with up to 50 micron accuracy and will make the wheels according to your parameters.

MACHINING

The process starts with uploading the 3D model to the CNС machine.

The blank is put into the Lathe machine to cut the contour of the blank according to a set program in three directions. Around 70% of material is removed by this process.

The design of the front face of the wheel is milled, the holes of the hub, PCD and nipple hole are drilled. Engravings are also applied at this stage. The process lasts from 6 to 30 hours depending on the design complexity.

FIRST STEP - 3D MODEL UPLOAD

SECOND STEP - LATHE TURNING

THIRD STEP - MILLING

PREPARATION FOR PAINTING

Polishing is a manual work and it’s performed in order to increase the adhesion of the paint to the wheel.

The wheels are consequenty put into 8 baths, each bath containing a special chemical solution for degreasing. This procedure is necessary to achieve an ideal result in painting.

POLISHING

DEGREASING

PAINTING

1) Diamond cut

2) Brushed

3) Mirror polishing

4) Tinting varnish

5) Rim stripe

6) Double colour

7) Plate

8) Engravement

9) Alternative colour engravement

10) Deepened face of the wheel

11) Decorative bolts

12) Spinner-cap

13) Brushed spinner-cap

2) Brushed

3) Mirror polishing

4) Tinting varnish

5) Rim stripe

6) Double colour

7) Plate

8) Engravement

9) Alternative colour engravement

10) Deepened face of the wheel

11) Decorative bolts

12) Spinner-cap

13) Brushed spinner-cap

ADDITIONAL OPTIONS:

Painting is done manually in 3 stages: priming, painting and varnishing. Colour options are not limited, any colour can be chosen according to your request. Glossy, matte and semi-matte varnishes are available.

Once the painting is finished the wheels are sent to the drying chamber.

Once the painting is finished the wheels are sent to the drying chamber.

PACKING

Each wheel undergoes a final quality check before being shipped out.

Vissol wheels are packed in multilayer carton boxes in order to prevent any damage caused during the transportation. For International shipments the wheels are additionaly packed into a wooden cage.

Vissol wheels are packed in multilayer carton boxes in order to prevent any damage caused during the transportation. For International shipments the wheels are additionaly packed into a wooden cage.

WHAT IS THE PRODUCTION TIME ?

faq

Standard production time is 2 weeks since the confirmation of the 3D model.

Note: does not include the delivery time.

Note: does not include the delivery time.

WHAT ARE THE PAYMENT TERMS ?

The payment is made in 2 parts: 50% prepayment before the start of production and 50% prepayment before shipment.

WHAT ARE THE WHEELS MADE OF ?

For Vissol wheels production we use 6061T alloy. It is based on aluminum with alloying additives of magnesium, copper, silicon, zinc and other metals, and is mainly used in aircraft industry.

WHERE IS VISSOL PRODUCTION FACILITY ?

Our production is located in Yaoslavl, Russia.

WHAT ARE THE AVAILIABLE SIZE ?

We produce 18-24 inch diameters.

DO YOU HAVE WHEELS ON STOCK ?

We do not sell from stock, we manufacture wheels exclusively for each Client and we implement the most unconventional solutions to make your car look truly unique.

CAN YOU GUARANTEE THAT WHEELS WILL FIT MY CAR?

We use TUV drawings to ensure the fitment. In case your car was tuned or has uknown specifications due to its rarity, you don't need to worry if our wheels will fit your car or not. With a 3D scanner we will get all the dimensions from your car with up to 50 micron accuracy and will make the wheels according to the measurements.

WHAT IS THE WEIGHT OF THE WHEEL ?

The wheel weight depends on the diameter, permissible gross weight of the vehicle, safety margin and wheels design. On average the weight of the wheels ranges between 8 and 20 kg based on the conditions mentioned above.

WHAT ABOUT DELIVERY?

For UAE we can deliver straight to your door or any auto shop of your choosing. For other countries delivery is made to airport terminal.

CAN YOU GURANTEE THE QUALITY?

We provide a life-time warranty for the wheel structure and 1 year warranty for the paint coating. Warranty for wheel accessories is six months.

CONTACT US

sales@vissol-wheels.com

VISSOL FORGED AUTO SPARE PARTS AND COMPONENTS TRADING L.L.C.

©2023 VISSOL

INQUIRE NOW

By clicking the button, you consent to the processing of personal data in accordance with the privacy policy and accept the terms of the user agreement.